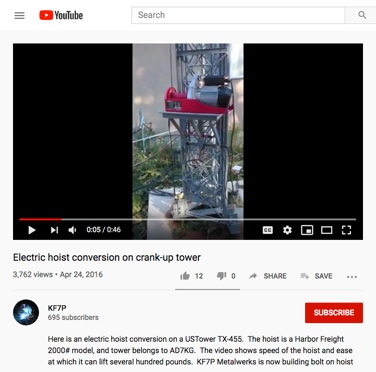

Well, Harbor Freight emailed me a 25% coupon last week so I picked up the hoist much earlier than I anticipated.

Saturday, May 26 I spent about an hour disassembling the old hoist. I had made it from the original hand-crank winch and a 1/9 horsepower reversible electric motor I had salvaged from an old height-adjustable office desk raising mechanism. I simply connected the motor gearbox to the winch crank handle with sprockets and a chain. It worked well but was necessarily geared way down so it took 25 minutes to raise or lower the tower.

Your hoist frame bolted to the tower with no alteration and took less than ten minutes to do. The mounting holes matched perfectly.

The next task was to remove the factory cable from the new Harbor Freight hoist. It took a bit of persuasion to get the spool free from it's bearing in the end of the frame but that job was done in a few minutes and the cable was removed after I took a photo of the way in which the cable end was attached to the spool. I knew I would have to duplicate that at the tower with the tower cable. By the way, in my case with the TMM 541 tower, the cable diameter was just 1/32 inch larger than the original cable on the hoist and went easily through the hole and retention slot in the spool. On a larger tower with larger diameter cable, some alteration of the spool would probably be needed.

It took about a half hour to attach the tower cable to the spool, reassemble the spool to the gearbox shaft and rebolt the hoist to its frame. Another half hour or so to position and bolt the hoist to your frame and the job was done. I got torque specs for the mounting bolts off the internet and everything is properly torqued. Here again, the mounting holes in your frame were perfectly matched to the Harbor Freight hoist and there were lots of alternative holes for proper alignment of the hoist and the tower cable. Total project time was less than three hours

The first raising went flawlessly. From bottom to top took less than 30 seconds. It was amazing!

It moves so quickly one has to be alert to when it reaches the end of the travel. I immediately did the first lowering and it also went perfectly.

Thanks for a well designed and wonderfully made product. It's a joy to use and will make tower and antenna maintenance and storm avoidance much easier. Feel free to use me as a reference for any customers who may want to talk to a satisfied customer.

KØRO